What is Stainless Steel Turning?

Stainless steel turning is the process of shaping stainless steel by cutting away the material of a workpiece, or by machining an internal radius into the surface.

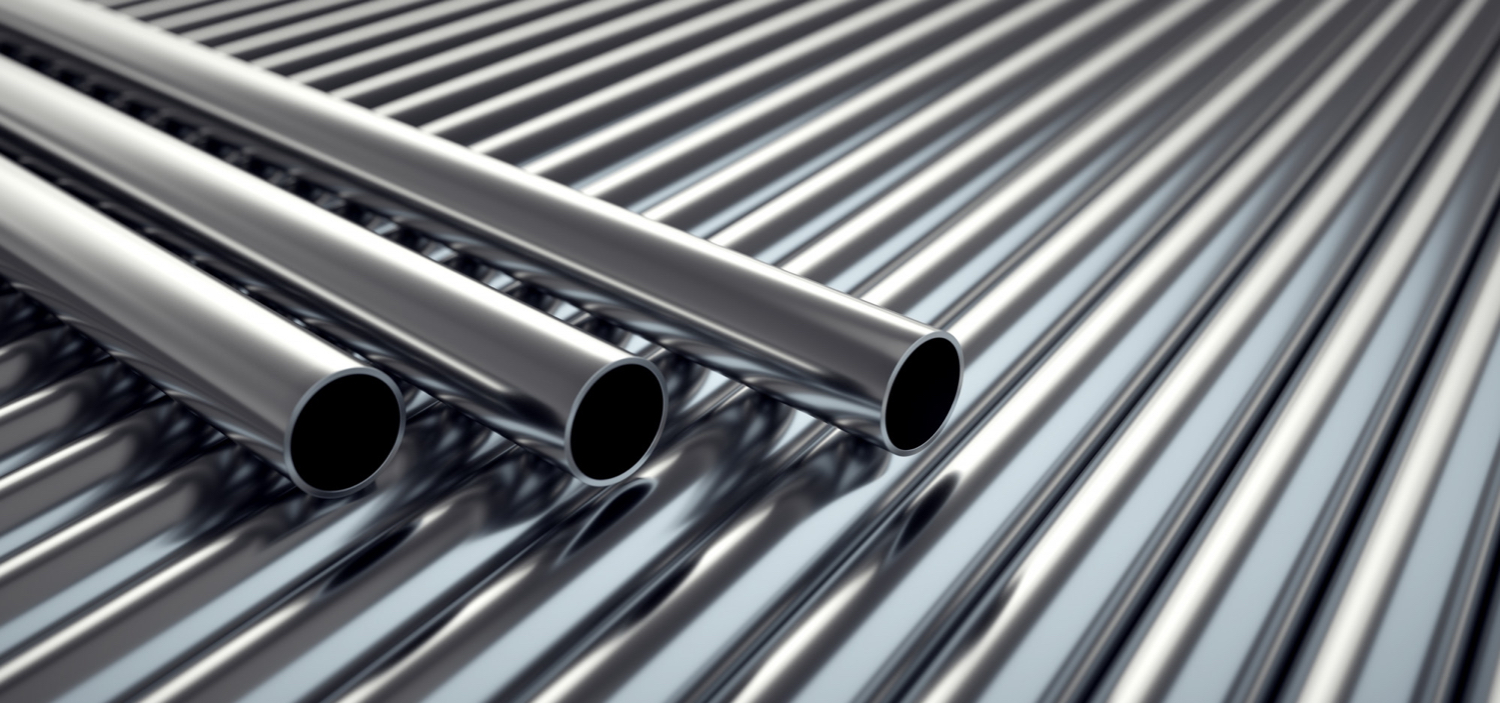

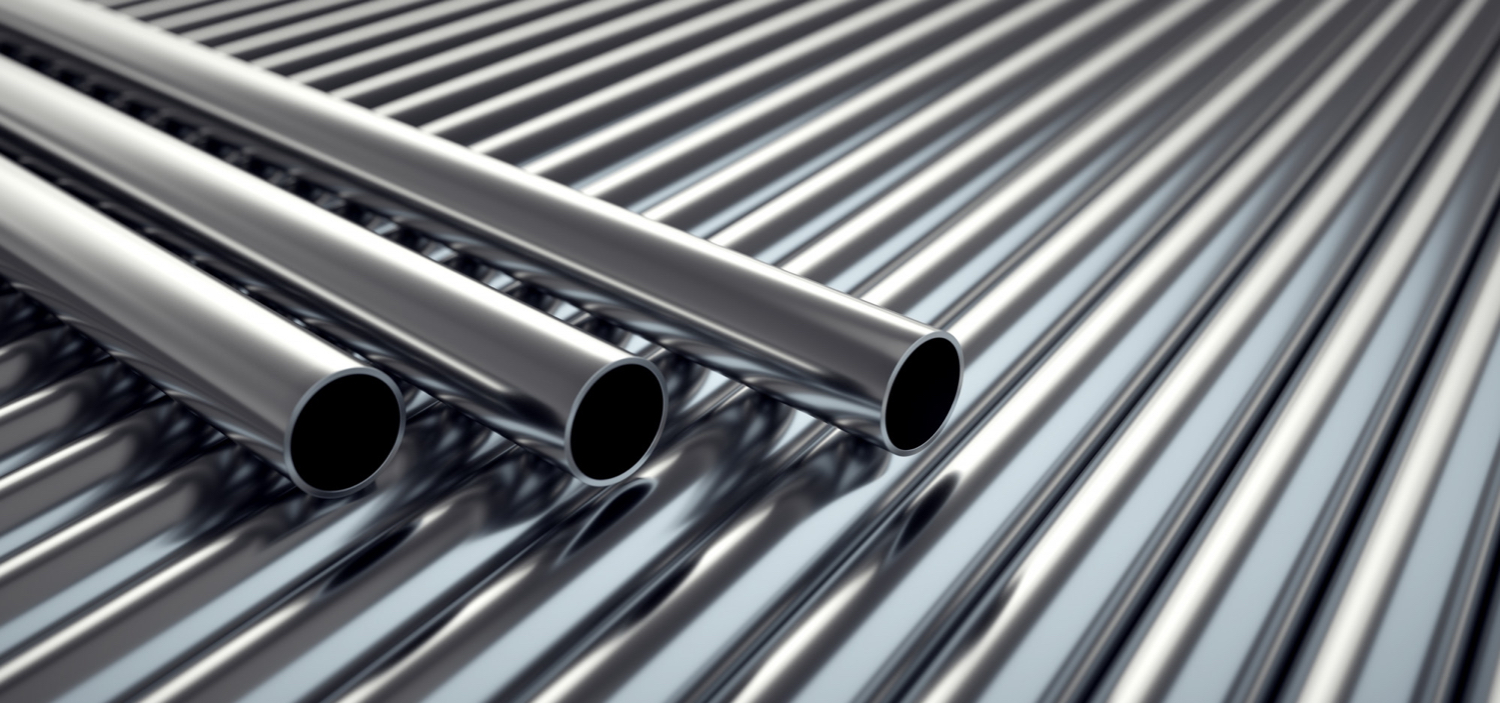

Stainless steel is made from iron with 18% chromium content, resulting in very hard metal and corrosion-resistant metal. It also has good strength properties over a wide temperature range.

Stainless steel turning can be used for applications such as medical instruments, automotive parts, toys, and many other products. Stainless steel can be turned by either manual or CNC lathes.

Types of Stainless Steel Turned Components

Stainless steel turned components are made from metal that has been shaped using a lathe. The lathe allows the metal to be cut into different shapes, ensuring that your stainless steel turned components will meet your specifications.

The following are some examples of the different types of stainless steel turned components:

Shafts — Shafts are used for connecting moving parts together, such as gears and pulleys. They can also be used as an axle on wheels or shafts that rotate freely in their sockets. Shafts come in two main sizes: round and square. A round shaft has a circular cross-section while a square shaft has an octagonal cross-section with flat sides and rounded corners.

Bolts — Bolts are threaded fasteners that are used to hold objects together by threading them through holes drilled into one object and then screwed into another object using nuts on the other side of the hole.

Screws — Screws are also threaded fasteners, but they differ from bolts in that they can be used without nuts. They have a tapered tip that helps them grip into the object being screwed and are often used to attach objects together.

The Stainless Steel Turning Components Process

Stainless steel turning components are used in a variety of industries and applications. From automotive parts to medical devices, there are many places where these components can be used. The process of making them is fairly simple but it does require some specialized equipment and a trained workforce.

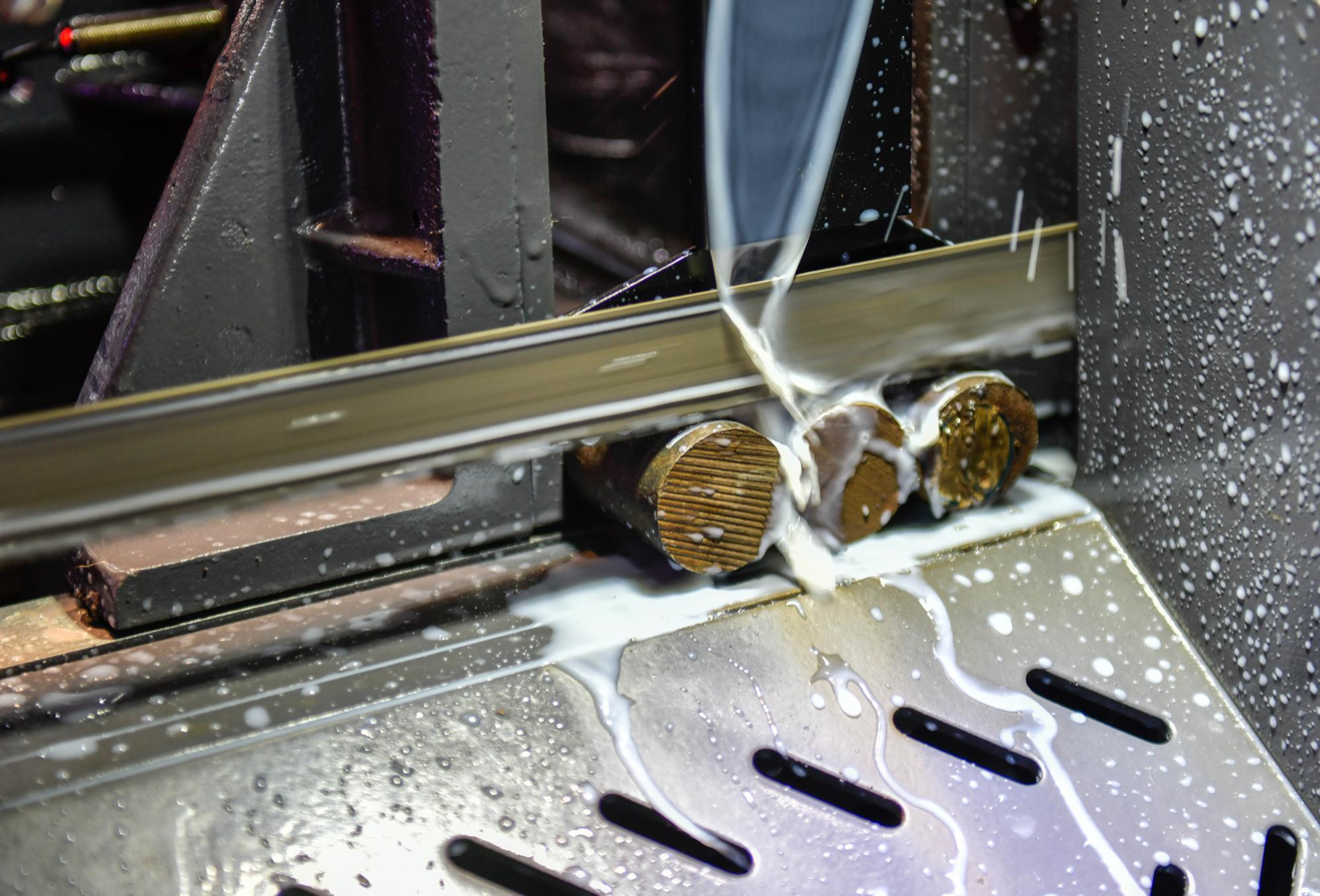

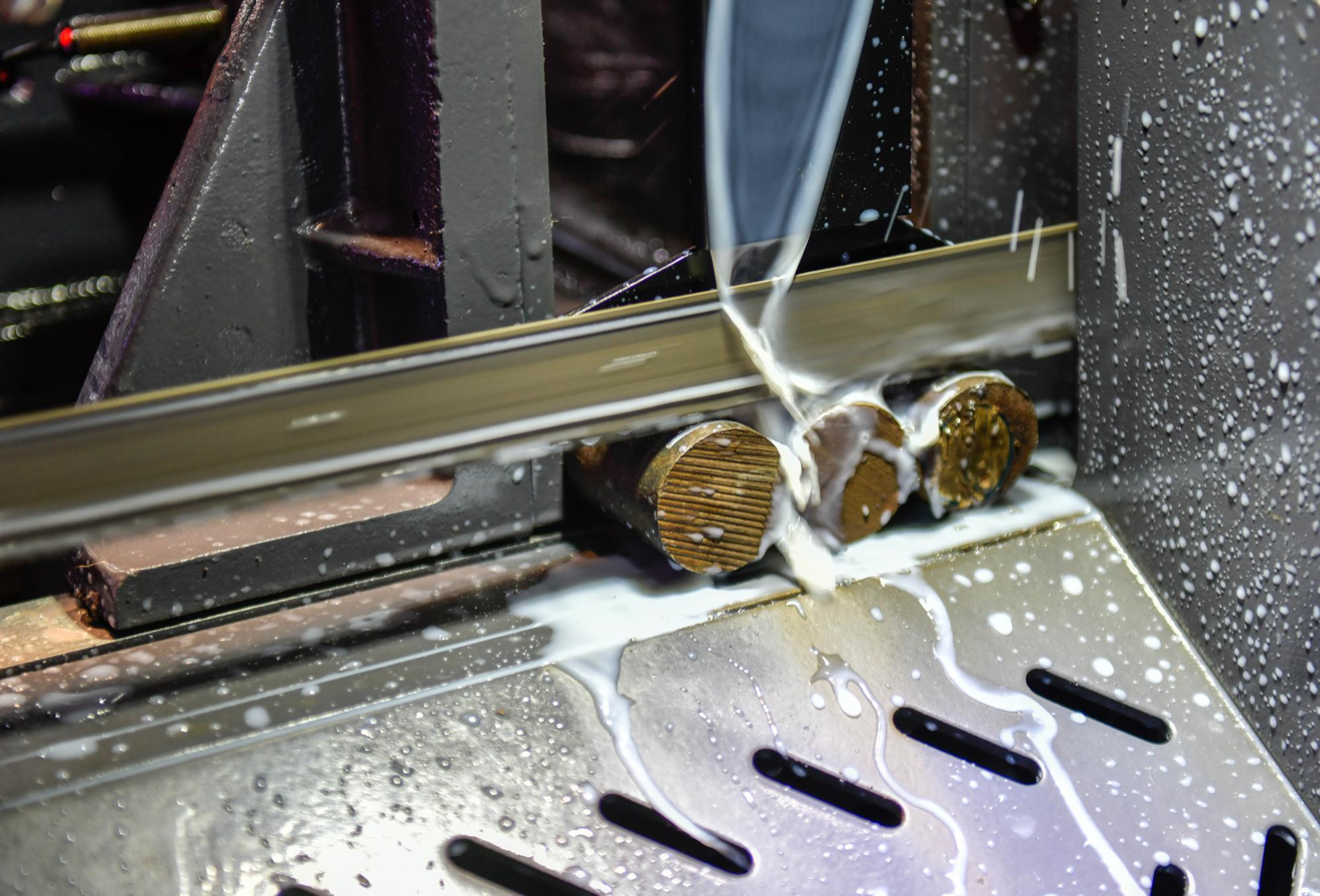

Turning stainless steel is similar to other metal turning processes in that the material is worked on a lathe using cutting tools. However, the tool bit is different because of the hardness of the metal being cut.

The first step in turning stainless steel components is roughing out the part from solid bar stock using a roughing end mill or fly cutter depending on its size and complexity. Once this has been done a finish end mill is used to finish it up and make sure there are no burrs left behind before finishing. Depending on the requirements of the part, a center drill may also be used.

After the component has been machined it is transferred to a CNC lathe where it can be given any final touches that might be required before being shipped out.

Uses for Stainless Steel Turning Components

Stainless steel turned components can be used in a number of applications, including:

Medical Devices — Stainless steel-turned components are often used in medical devices such as surgical instruments, stents, catheters, and other equipment. These products are designed to be sterilized, which makes them ideal for use in hospitals and other medical facilities.

Chemical Products — Stainless steel can also be used to produce chemical products such as tanks and vats for storing chemicals or liquids. It is also used in distillation columns where chemicals are processed at high temperatures and pressures using heat transfer methods.

Food Processing Equipment — Stainless steel is commonly used to produce various food processing equipment such as mixers, blenders, and other appliances that handle food items. In addition, it can be used in dishwashers and washing machines because it withstands harsh cleaning chemicals without corroding or rusting over time.

Industrial Machinery — Stainless steel is used in industrial machinery to produce parts that are exposed to harsh environments. These include parts such as conveyor belts, hoppers, screws, and blending equipment that come into contact with water and cleaning chemicals on a regular basis.

Household Appliances — Stainless steel is used in household appliances all around the world, including refrigerators and stoves because it does not rust or corrode when exposed to water. In addition, it can be cleaned easily and has a high resistance to corrosion.

What Tools are Used for Stainless Steel Turning

The most common tools used to do stainless steel turning are the same as those used on other metals.

Lathes: If you want to turn a stainless steel part, you’ll need a lathe. Lathes are machines that spin your workpiece and allow you to cut away at it with tools called cutting tools (also known as “cutters”).

Cutting Tools: Cutting tools come in several varieties — such as endmills, drill bits, and taps — but the main thing they have in common is that they’re made of hardened steel so that they can cut through metal without becoming dull or breaking.

Fixtures: Fixtures hold your workpiece in place while the lathe does its work. They also help guide parts to position so that they’re easy to access by the operator and tooling.

Lubricants: Lubricants are used between cutting tools and workpieces to reduce friction and ensure the smooth operation of machinery. This helps extend tool life and prevents smearing or galling (when two surfaces stick together).

Milling Cutters: Milling cutters are special types of cutting tools made for milling machines, which are used in manufacturing. Endmills, drill bits, and taps are just some examples of these cutters. They’re made of hardened steel so that they can effectively cut through metal without breaking or dulling easily.

Our Stainless Steel Turning Parts Capabilities

At Gayatri Precision, we offer Stainless Steel Components made from high-quality material and tested on various parameters before delivering to our customers. We are one of the leading providers of CNC machined parts and components with expertise in delivering high-quality products.

The stainless steel turning parts we offer are known for their high efficiency and easy maintenance, which makes them extremely durable.

Our team of highly experienced professionals keeps a close eye on the production process to ensure that all the products manufactured are up to the mark.

So, if you are looking for a reliable and trustworthy partner to outsource your CNC machining requirements, then Gayatri Precision is the right choice for you.

To know more about us, please visit our website or contact our team directly to place your order.