What are Pipe Fittings?

Pipe fittings are used to join pipes together. Pipe fittings are available in a variety of materials such as brass, copper, and stainless steel. They are also available in various sizes and shapes.

The most common pipe fittings that you can find in the market are butt welded fittings, socket welded fittings, threaded fittings, and flanged (or slip-on) type of pipe fitting.

The size of the pipe fitting depends on its application and it should match with the other end of the pipes perfectly so that there is no leakage or improper functioning after installation.

For example: a ¼” female adapter will fit on ¼” male pipe threads but not into ½” male threads because it does not have enough room for extra threading inside it making it loose onto ½”.

The best thing about this type of fitting is you can use them easily at home without any major assistance from professionals or experts which makes them cost-effective too as compared to other types like flange types where professional assistance would be required during the installation process so these two factors combined makes them popular among homeowners as well as contractors alike.

What are Pipe Fittings Components?

Pipe fittings components are the parts that are used to connect pipes. The pipe fitting components are made of metal or plastic. In some cases, you may even see them in a combination of both metals and plastics.

These fitting components can be used to connect pipes of different diameters, lengths, and other specifications.

Types of Pipe Fittings

There are many different types of pipe fittings available, each designed for a specific purpose.

The most common types include:

- Bends – Used to connect two different lengths of piping or tubing at an angle.

- Reducers – Reduce the inside diameter (ID) of a pipe, fitting, or tubing by cutting off part of the end and re-threading it.

- Tees – Connects two pipes at a right angle to each other so they cross over each other at one point. This creates an input port on one side and two output ports on the other side.

- Couplings – Connects two pipes or fittings together even if the end sizes are different.

- Unions – Similar to couplings, except they can be easily disassembled and re-assembled for maintenance purposes.

- Caps – Used to cover the open end of a pipe or a fitting.

The Pipe Fittings Machining Process

The pipe fittings machining process begins with the selection of the material to be used. Once the material has been selected, it must be cut into the correct shape and size.

The next step is to bore a hole at each end of the pipe fitting. The hole is bored so that a bolt can pass through it. The hole can be drilled or sawed depending on the type of pipe fitting being made and whether it requires an internal or external thread.

Once both ends have been bored out, one side is threaded for the pipe. A die with a matching thread is used to cut threads into one side of the pipe fitting. The other side may also be threaded if needed, but this isn’t always necessary depending on what type of pipe fitting you’re making and how you plan to install it.

The final step in making a pipe fitting is deburring all sharp edges and smoothing any rough spots so that it’s safe for use by consumers when installed at home or in commercial settings such as restaurants and hotels

What Tools are Used for Pipe Fittings Machining?

Pipe fittings machining is a type of work that can be done in several ways. The most common tooling used for this process includes:

- CNC machining

- CNC milling

- CNC turning

- CNC grinding

- CNC wire EDM (Electrical Discharge Machining)

- CNC wire cutting

- CNC wire erosion (Electro Discharge Machining)

Uses for Pipe Fittings Machined Parts

Pipe Fittings Machined Parts are used in a variety of industries, including the Oil & Gas Industry and the Power Generation Industry.

Pipe Fittings Machined Parts can also be found in:

- Pipe fittings can be used to connect pipes together in plumbing systems. For example, you could use them to create a leak-proof connection between two pipes that carry water or gas.

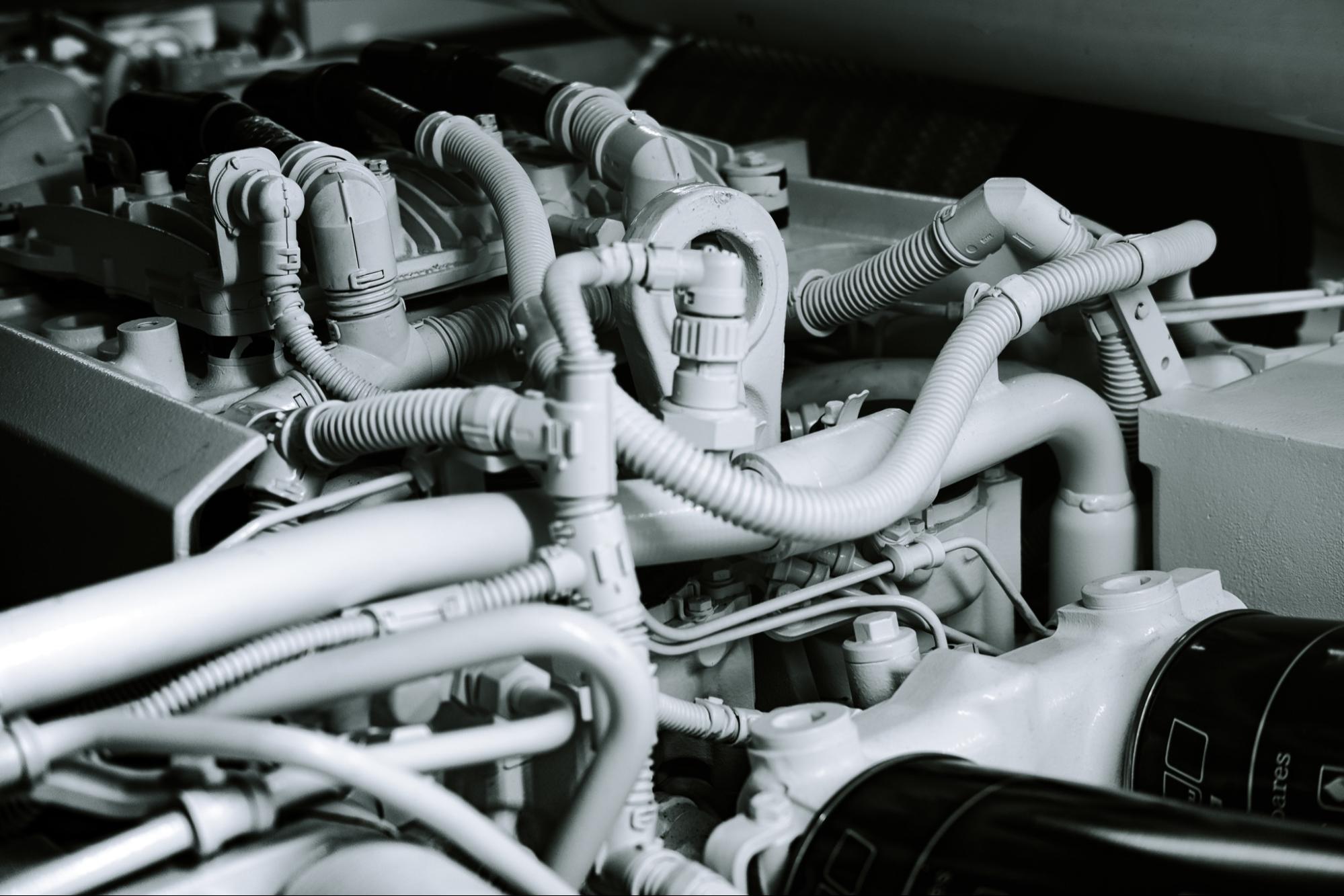

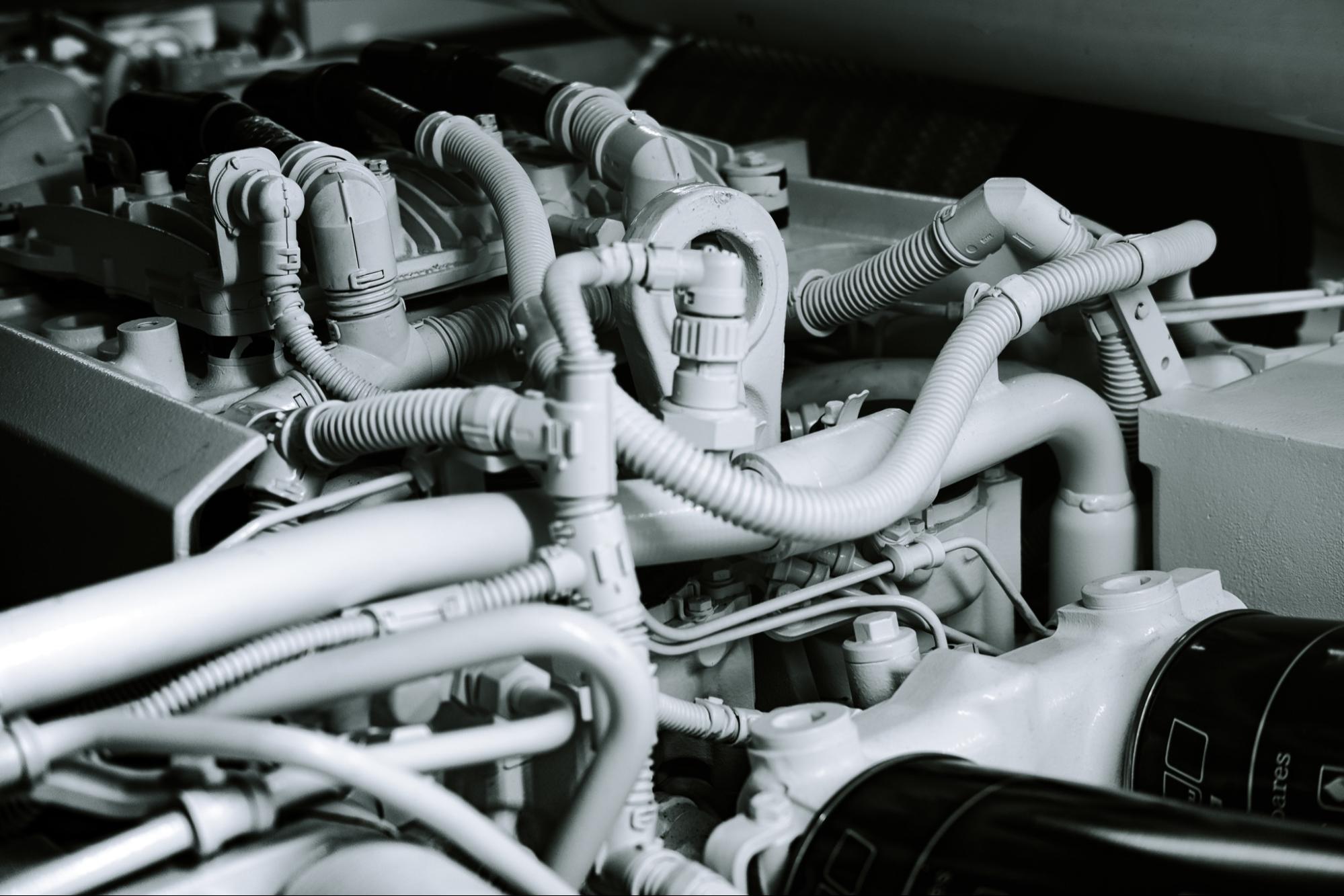

- They can also be used on industrial equipment such as boilers, turbines, and engines where they will connect different parts together so they work together properly.

- Another common use is with air ducts in buildings where they help support the weight of air ducts while allowing them to move freely through an area without causing any damage or discomfort for those who are nearby (such as yourself).

Pipe Fittings Machined Parts are important components to these industries because they connect pipes in order to transport fluids and gases.

Our Pipe Fittings Manufacturing Capabilities

Gayatri Precision is a renowned manufacturer, exporter, and supplier of high-quality Pipe Fittings.

We offer precision Pipe Fittings that are made from high-quality material and are tested on various parameters before delivering to our customers.

Our Pipe Fittings can be availed in different specifications as per the requirements of our clients. The offered products are manufactured using advanced machines under the supervision of experienced professionals at an advanced production unit.

If you want to know more about us, please visit our website or contact our team directly to place your order.

Conclusion

We hope that you have found this article to be a helpful resource. If you are looking for more information on pipe fittings and their machining process, please contact us!

We would be happy to answer any questions you may have as well as provide some more details about our capabilities here at Gayatri Precision.