What is Precision Machining?

Precision machining is the process of cutting or shaping metal using highly controlled cuts. The process is often used to create parts for machines and other products.

The term “precision” in precision machining means that the machined part should be made to very close tolerances, with very little variation in size or shape.

Precision machining includes a variety of different processes, including turning, milling and grinding. These are used to create everything from simple hardware to complex pieces of machinery.

What are Precision Machined Components?

Precision Machined Components are a subset of machined components. The difference is that precision machined components have very tight tolerances, and are usually very small in size.

Precision machined components are made to tight specifications, and can be made from a wide variety of materials including plastic and metal.

The Precision Machining Process

The first step in the precision machining process is to design the part. This step is important because it determines how well the part will fit into other components of the product. The designer must also take into account any changes that may be needed during production or after installation.

Once a design has been created, it must be converted into a drawing or CAD file that can be read by machine operators. These files are then sent to a programmer who creates code for CNC machines that can cut out each piece of metal with great accuracy and precision.

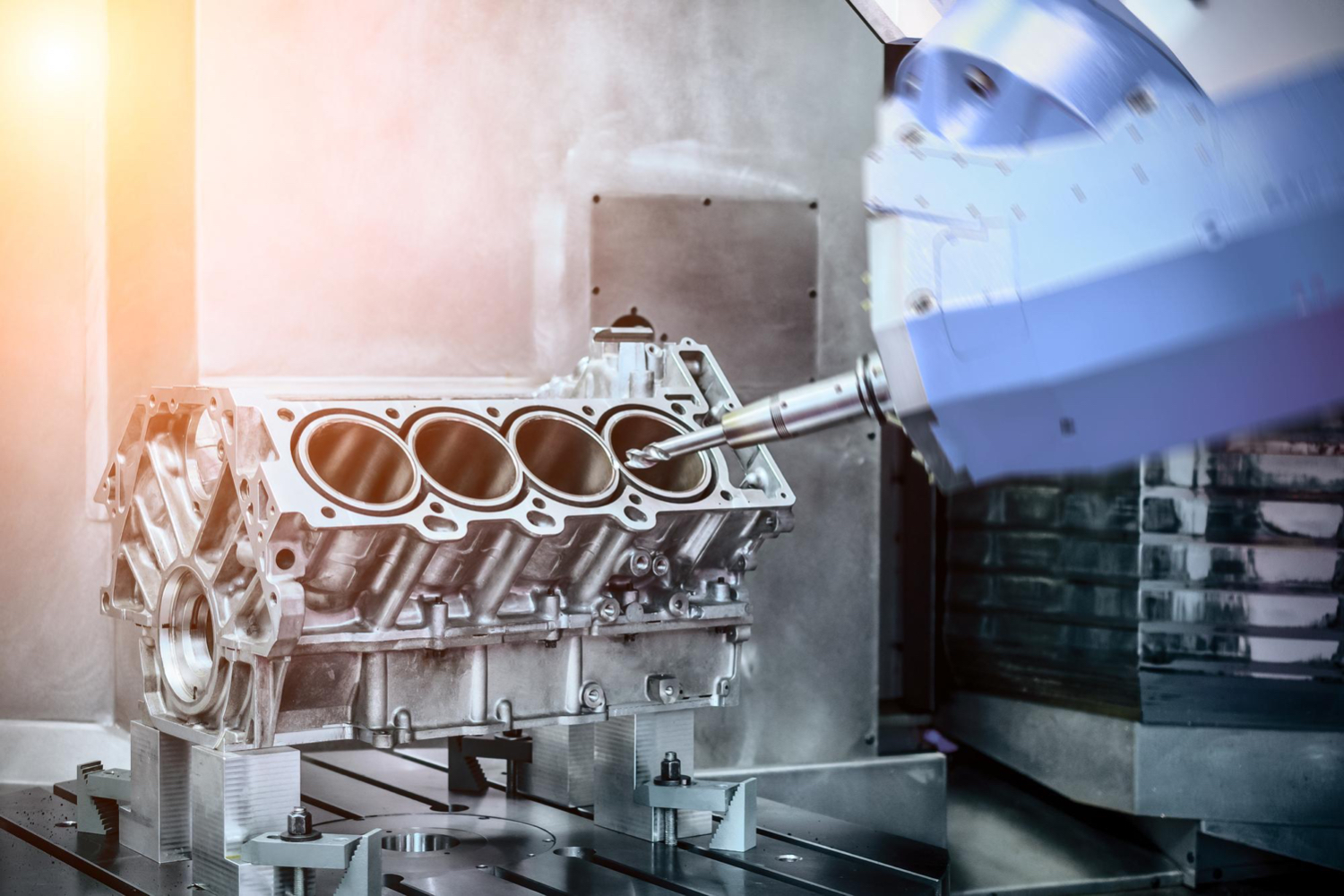

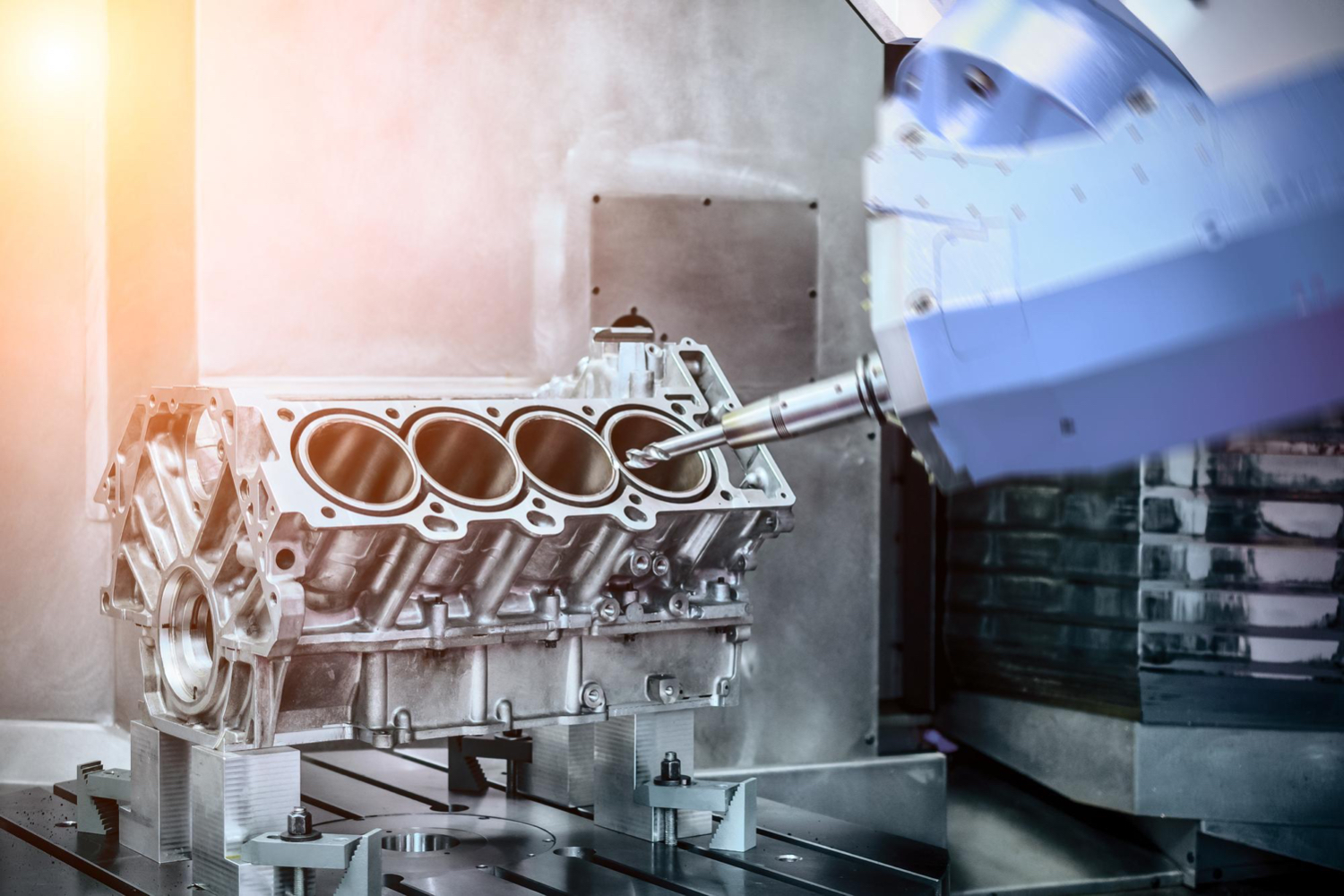

Next, machinists use high-speed tools and machines to cut out each individual piece of metal from larger sheets or blocks of raw material like aluminum or steel. They also use these tools to drill holes and create other necessary features like slots or grooves in each piece of metal.

After all pieces have been cut out and drilled as needed, they are cleaned up with hand tools like chisels before being inspected by inspectors who look for any defects in shape, size or surface finish before moving on to the next step in production.

What Tools are Used for Precision Machining?

Precision machining requires very specific tools in order to produce the desired results. These include:

Lathes: These are commonly used for turning metal into shapes that are more complex than possible with other methods. Lathes can be manual or automated depending on the needs of the job at hand.

Milling Machines: Milling machines are used for cutting away material from a workpiece in order to create holes or other features that would otherwise be impossible to achieve with a lathe alone. They also perform some secondary operations like drilling holes and boring out deep cavities quickly and accurately.

Drills & End Mills: Drill bits are used to drill holes through metal parts while end mills are used to machine features such as slots, grooves and cylindrical surfaces into workpieces at high speeds without losing control over the tool path during operation.

Grinders: Grinders are used to remove material from workpieces in order to create a desired finish or shape.

Sanders & Polishers: Sanders andPolishers are finishing tools that smooth away surface imperfections, leaving behind a clean and uniform finish.

Uses for Precision CNC Machined Parts

Here are some common uses for precision CNC machined parts:

Aerospace — When you’re building a plane or spacecraft, precision is essential so that all of the parts fit together properly and function as intended. You need to make sure that everything fits together before you take off so that you don’t lose control of your plane or spacecraft during flight.

Automotive — Cars require many different types of precision CNC machined parts so that they can operate properly and safely on the road.

Medical Devices — Precision CNC machined parts are used in a variety of medical devices because they can be made to very precise tolerances. This allows them to fit properly with other components in the device and ensure it works as intended.

Electrical Components — Precision CNC machining is used to create electrical components such as capacitors, resistors, transistors, circuit boards and more. These components are needed for electronics like computers and cell phones, as well as other devices like televisions, radios and microwaves.

Our Precision Machined Parts Capabilities

At Gayatri Precision, we offer precision CNC machined parts that are made from high-quality material and are tested on various parameters before delivering to our customers. We are one of the leading providers of CNC machined parts and components with expertise in delivering high quality products.

We have been serving customers from all over the world for more than 28 years and we have built a strong reputation for providing quality products at affordable prices.

We also have a team of skilled and experienced engineers who check the quality of these parts at each stage of production. This ensures that only best quality products are delivered to our customers.

If you want to know more about us, please visit our website or contact our team directly to place your order.